Key points of EN1090 certification:

EN1090 belongs to the System2+category under the CPR regulations for building materials, mainly including factory production control, initial type testing, continuous supervision and evaluation, etc.

EN1090 certification is an audit of the steel structure enterprise system. The main assessment is the quality control capability of the enterprise. This mainly includes: welding personnel qualifications, material certificates, quality control documents, establishment of welding system, and product testing.

The general points that need to be certified are as follows:

a. Establish a factory production control system FPC; Refer to EN 1090-1, 6.3, P19;

b. Select execution level EXC1-4; Refer to EN 1090-2, A.3, P107;

c. Material certificate verification; Refer to EN 1090-2, 5, P25,

d. Establish a welding system; Refer to EN 1090-1, Table B.1, P26;

e. Determination of product performance parameters; Refer to EN 1090-1, ZA. 1, P30; f. Sign the declaration of conformity and use the CE label.

FPC audit points:

1. General requirements: Establish a factory control system based on ISO9001 document requirements to ensure that the products launched on the market are consistent with the performance parameters declared by the manufacturer The FPC system should include program files, inspection procedures, product testing, sampling, and verification records The inspection results are used to control product quality, production process documents, and production flow charts.

2. Welder certificates and welding operator certificates that meet EU standards for personnel

3. Measurement and calibration of weighing equipment, inspection equipment, and testing equipment Program file control

4. Structural design process evaluation, design calculation, evaluation in accordance with European standards

5. Material certificates or documents for the constituent materials (raw materials), such as 3.1 certificates, 2.2 documents (internal to the factory), or 3.2 certificates issued by third parties.

6. Material specifications provide basic performance requirements, basic performance verification, and records

7. Final product inspection

8. Process for handling non-conforming products

9. The factory provides an initial type testing report internally, which can be executed by the factory itself or operated by a third-party laboratory.

10. Welding system qualification certificate includes welding process (WPQR/WPAR), base metal, execution level, and standards. Provide welding manuals, etc.

For specific questions, please consult Zealous Cert Central Certification

National Unified Service Hotline: 021-65220665; 4008-220-990

Email:jenniferwang@zealct.com

ISO3834 International Welding System Certification

ISO3834 International Welding System Certification EN15085 International Welding Certification for Rail Vehicle Components

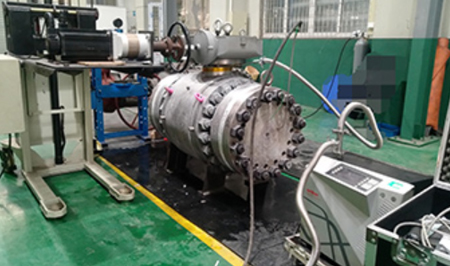

EN15085 International Welding Certification for Rail Vehicle Components API 607, 6FA Valve Fire Resistance Test

API 607, 6FA Valve Fire Resistance Test ISO15848 Valve Low Leakage Certification

ISO15848 Valve Low Leakage Certification API 622 Valve Packing Type Test for Anti Leakage Process

API 622 Valve Packing Type Test for Anti Leakage Process Type testing of API 624 lifting rod valves with FE graphite packing

Type testing of API 624 lifting rod valves with FE graphite packing EN1090 certified steel structure

EN1090 certified steel structure MID Metrology Certification

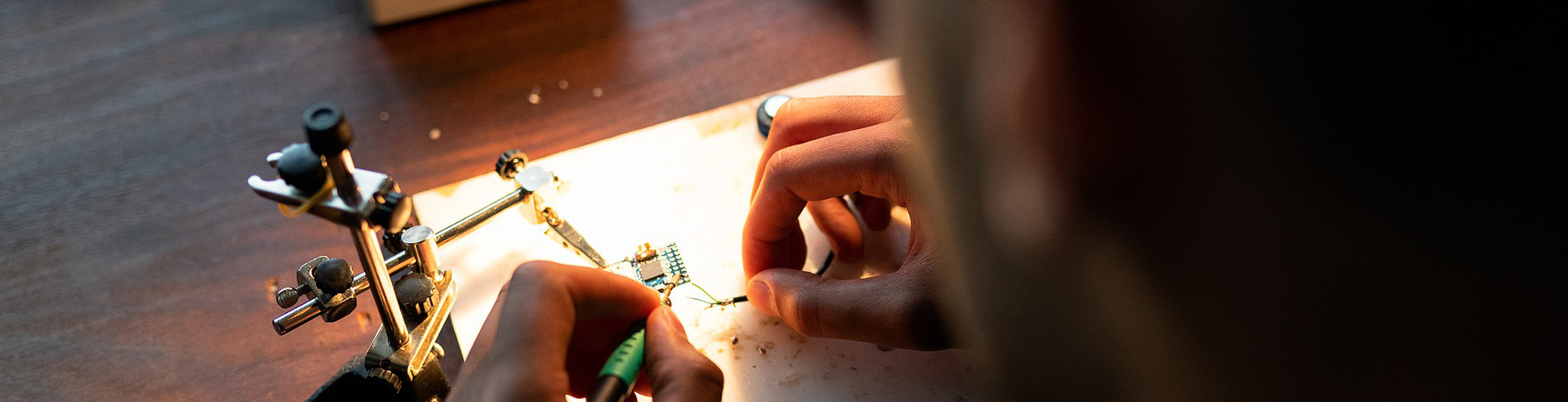

MID Metrology Certification RoHS Hazardous Substance Certification

RoHS Hazardous Substance Certification ISO9001 Quality Management System Certification

ISO9001 Quality Management System Certification CN

CN

About us

About us Corporate culture

Corporate culture Our services

Our services Our advantages

Our advantages Our mission

Our mission SIL certification

SIL certification  PED certification

PED certification  ATEX certification

ATEX certification  API certification

API certification  CE certification

CE certification  Mechanical MD certification

Mechanical MD certification  Medical device MDD certification

Medical device MDD certification  CPR certification of building materials

CPR certification of building materials  Elevator LIFT certification

Elevator LIFT certification  Yacht RCD certification

Yacht RCD certification  Zhonglue Information

Zhonglue Information Technical Exchange

Technical Exchange International Development

International Development Certified Encyclopedia

Certified Encyclopedia Contact information

Contact information Message

Message Jobs

Jobs Certificate Query

Certificate Query