Introduction to MD Mechanical Instructions:

2006/42/EC (old: 98/37/) EC Machinery Directive

The earliest Machinery Directive 89/392/EEC was issued on June 14, 1989, came into effect on January 1, 1993, and became a mandatory directive for CE marking on January 1, 1995. This directive was later replaced by the new Machinery Directive 98/37/EC on June 12, 1998. The latest Machinery Directive 2006/42/EC has been enforced since December 29, 2009.

Machinery refers to a whole composed of many interconnected parts and devices, in which at least one part is in motion (note: including movement and rotation). Mechanical hazard refers to the potential harm caused by the mechanical action of parts, cutting tools, workpieces, liquid and gaseous substances, etc. The Machinery Directive requires measures to be taken to avoid or reduce the hazards present in machinery, in order to ensure the health, property, and environmental safety of humans (animals).

Scope of MD Mechanical Directive:

1. Mechanical

2. Interchangeable devices

3. Security components

4. Lifting machinery accessories

5. Chains, ropes, and wire mesh belts

6. Detachable mechanical transmission equipment

7. Semi finished machinery

Required documents for mechanical CE certification:

1. CE Application Form

2. Trademark, business license

3. Product information: Name, model, technical parameter table (if there are multiple models, comparative data on differences between series products is required)

4. Mechanical assembly drawing and control system diagram

5. Mechanical user manual

6. Component List

7. Mechanical installation/operating space/operator location map

Mechanical authentication mode:

In the directive, machinery can be divided into two categories: ordinary machinery and dangerous machinery. The 17 categories of dangerous machinery are detailed in Appendix IV of the directive, and regulations also have higher safety assessment requirements for dangerous machinery.

Ordinary mechanical authentication mode:

-Internal Production Control of Annex VIII

Dangerous machinery certification mode:

1. Manufacturers produce according to coordinated standards

-Internal Production Control of Annex VIII

-EC type testing for Annex IX and internal production control for Annex VIII

-Annex X's comprehensive quality assurance

2. The manufacturer did not produce according to the coordinated standards

-EC type testing for Annex IX and internal production control for Annex VIII

-Annex X's comprehensive quality assurance

For specific questions, please consult Zealous Cert Central Certification

National Unified Service Hotline: 021-65220665; 4008-220-990

Email: jenniferwang@zealct.com

ISO3834 International Welding System Certification

ISO3834 International Welding System Certification EN15085 International Welding Certification for Rail Vehicle Components

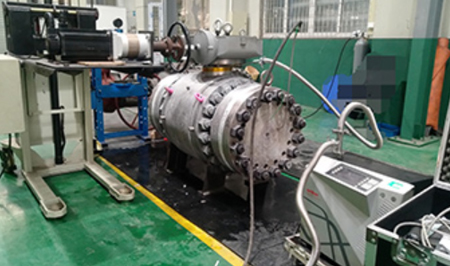

EN15085 International Welding Certification for Rail Vehicle Components API 607, 6FA Valve Fire Resistance Test

API 607, 6FA Valve Fire Resistance Test ISO15848 Valve Low Leakage Certification

ISO15848 Valve Low Leakage Certification API 622 Valve Packing Type Test for Anti Leakage Process

API 622 Valve Packing Type Test for Anti Leakage Process Type testing of API 624 lifting rod valves with FE graphite packing

Type testing of API 624 lifting rod valves with FE graphite packing EN1090 certified steel structure

EN1090 certified steel structure MID Metrology Certification

MID Metrology Certification RoHS Hazardous Substance Certification

RoHS Hazardous Substance Certification ISO9001 Quality Management System Certification

ISO9001 Quality Management System Certification CN

CN

About us

About us Corporate culture

Corporate culture Our services

Our services Our advantages

Our advantages Our mission

Our mission SIL certification

SIL certification  PED certification

PED certification  ATEX certification

ATEX certification  API certification

API certification  CE certification

CE certification  Mechanical MD certification

Mechanical MD certification  Medical device MDD certification

Medical device MDD certification  CPR certification of building materials

CPR certification of building materials  Elevator LIFT certification

Elevator LIFT certification  Yacht RCD certification

Yacht RCD certification  Zhonglue Information

Zhonglue Information Technical Exchange

Technical Exchange International Development

International Development Certified Encyclopedia

Certified Encyclopedia Contact information

Contact information Message

Message Jobs

Jobs Certificate Query

Certificate Query