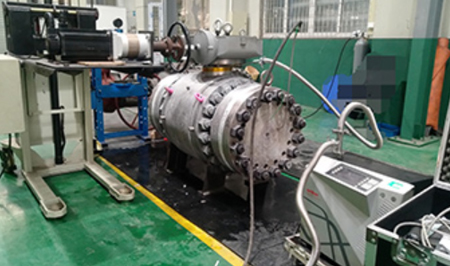

The API 624 standard specifies the acceptance criteria (100ppmv) for low leakage type testing of open stem and lift rotary stem valves with graphite packing. Previously, it was tested according to API 622, and the packing must meet the requirements for use at -29 ° C to 538 ° C (-20 ° F to 1000 ° F). The requirements included in this type of test are based on the principles of EPA21. Valves with dimensions greater than NPS24 or pressures greater than class 1500 are not included in this standard.

Result evaluation: Methane leakage during the testing process

Attention: No adjustments are allowed to be made to the filling part during the testing process

Customer provided: Prototype (including packing), packing API622 qualified testing report

The API624 test medium is methane with a minimum purity of 97%, which undergoes 310 mechanical cycles, including 3 thermal cycles, with a high temperature cycle temperature of 260 ℃± 5%.

During the testing process, it is not allowed to adjust the packing. The leakage value during the entire testing process should not exceed 100ppm to be considered qualified.

During the experiment, our engineers will arrive at the site for third-party witnessing

The price of API624 needs to be determined based on the valve size and pressure rating

The API624 standard specifies the requirements and acceptance criteria (100ppmv) for low leakage type testing of open stem and lift rotary stem valves with graphite packing, which were previously tested according to API622. The filler must be used at temperatures ranging from -29 ° C to 538 ° C (-20 ° F to 1000 ° F). The requirements included in this type of test are based on the principles of EPA21. Valves with dimensions greater than NPS24 or pressures greater than class 1500 are not included in this standard.

API 624 result evaluation:

1. Methane leakage during the testing process;

2. No adjustments are allowed to be made to the filling area during the testing process.

The scope of qualified valves is covered, and not every model of valve needs to be made in a batch, so the principle of coverage can be followed.

Zeus Zhonglue Certification Valve Related Certification Services:

1. Valve PED 2014/68/EU, CE-PED certification

2. Explosion proof CE-ATEX certification for valves, actuators, etc

3. SIL functional safety certification for valves, actuators, etc

4. Valve API 6A, 6D certification

5. Valve API 607,6FA fire resistance test

6. Valve ISO15848 Micro Leakage Test

For specific questions, please consult Zealous Cert Central Certification

National Unified Service Hotline: 021-65220665; 4008-220-990

Email: jenniferwang@zealct.com

ISO3834 International Welding System Certification

ISO3834 International Welding System Certification EN15085 International Welding Certification for Rail Vehicle Components

EN15085 International Welding Certification for Rail Vehicle Components API 607, 6FA Valve Fire Resistance Test

API 607, 6FA Valve Fire Resistance Test ISO15848 Valve Low Leakage Certification

ISO15848 Valve Low Leakage Certification API 622 Valve Packing Type Test for Anti Leakage Process

API 622 Valve Packing Type Test for Anti Leakage Process Type testing of API 624 lifting rod valves with FE graphite packing

Type testing of API 624 lifting rod valves with FE graphite packing EN1090 certified steel structure

EN1090 certified steel structure MID Metrology Certification

MID Metrology Certification RoHS Hazardous Substance Certification

RoHS Hazardous Substance Certification ISO9001 Quality Management System Certification

ISO9001 Quality Management System Certification CN

CN

About us

About us Corporate culture

Corporate culture Our services

Our services Our advantages

Our advantages Our mission

Our mission SIL certification

SIL certification  PED certification

PED certification  ATEX certification

ATEX certification  API certification

API certification  CE certification

CE certification  Mechanical MD certification

Mechanical MD certification  Medical device MDD certification

Medical device MDD certification  CPR certification of building materials

CPR certification of building materials  Elevator LIFT certification

Elevator LIFT certification  Yacht RCD certification

Yacht RCD certification  Zhonglue Information

Zhonglue Information Technical Exchange

Technical Exchange International Development

International Development Certified Encyclopedia

Certified Encyclopedia Contact information

Contact information Message

Message Jobs

Jobs Certificate Query

Certificate Query